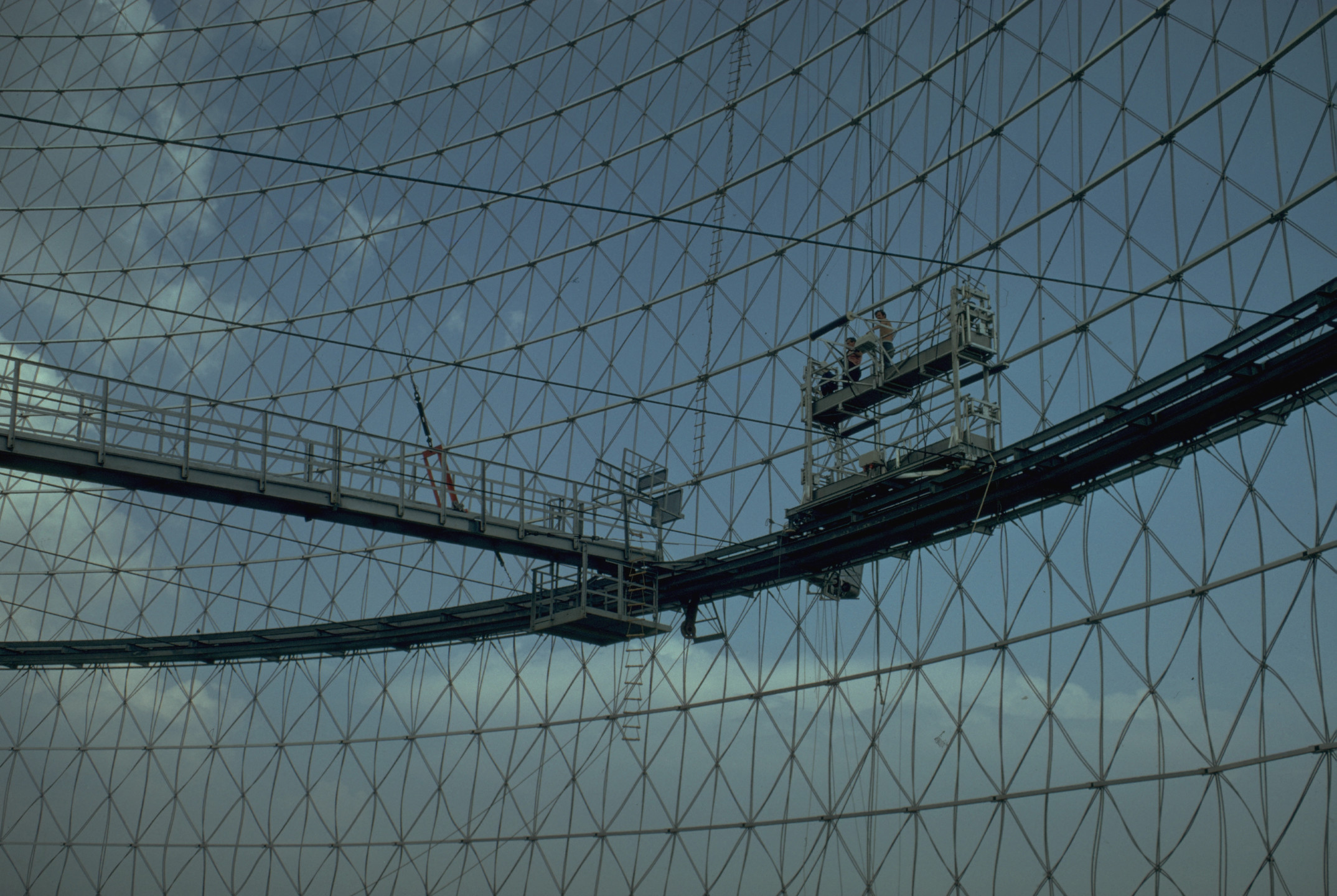

The Cable Net Cooling Tower for the Hamm-Uentrop nuclear power plant in Schmehausen, a part of the town of Hamm, represents a prototype for the testing of a new cooling process – dry cooling – and a new structure: a cable net.

A cable net of triangular meshes spans between a concrete foundation ring, secured firmly in the ground, and a steel ring at the top. This compression ring hung like an advent wreath at the tip of a centric concrete mast, pre-stressing the cable net against the mast. The net is coated on the inside with trapezoidal corrugated sheet aluminium.

Initially, the plan was to make the skin from a textile membrane. Structurally speaking, a membrane is equal to a cable net made of triangular meshes. Both structures can only cope with the forces of wind if pre-stressed. However, since there can be strong wind when the membrane is being hoisted into position, possibly causing the untautened membrane to tear, it was cable net that was chosen.

The form of the rotation hyperboloids ensured that during pre-stressing – by lifting of the upper compression ring – all cables were equally pulled. After pre-stressing, the non-structural aluminium sheet cladding was fixed to the net nodes from the interior side. The net cables were prefabricated and delivered including pressed-on clamps, and got fixed to the compression ring. During lifting, the cables were rewinded and meanwhile the clamps of the three cable arrays bolted down.

Power generation was discontinued in 1989 and the cooling tower was dynamited in 1991.